Summary:

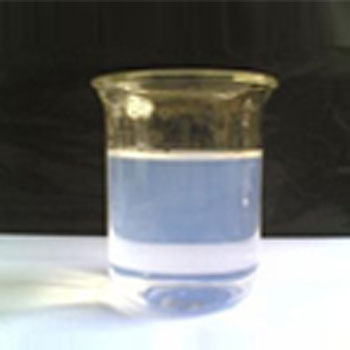

Our company's own research and development of nano alumina transparent liquid XZ-LY101 body color colorless transparent color solid content of 20%-25%. The use of nano alumina transparent liquid is 5-10 nano alumina, the 5-10 nano alumina nano alumina after the original particle size is slightly larger after three oxidation layers of deep processing were screened out of two aluminum, with obvious nanometer blue phase, added to a variety of acrylic resin, polyurethane resin, epoxy resin, melamine resin, water liquid silicone acrylic emulsion resin, adding 5% to 10%, can significantly improve the hardness of resin, the hardness is up to 6-8H or even higher. Completely transparent, the nano alumina liquid is water, because of the relatively small size of nanoparticles, regardless of what kind of solvent are solid and transparent, and can do all kinds of glass coating materials, gemstones, precision instruments and materials etc..

Performance characteristics:

Name

|

Nano alumina transparent liquid

|

Model

|

XZ-LY101

|

Appearance

|

Water clear

|

Solid content

|

20%-25%

|

Addition amount

|

5%-10%

|

hardness

|

6-8h

|

Nature:

1. nano alumina transparent liquid XZ-LY101 transparent, high content. No precipitation and no stratification.

2. nano alumina transparent liquid XZ-LY101 liquid, transparent, compatibility is very good.

3. nano alumina transparent liquid XZ-LY101PH=7.0 but the specific pH value can be adjusted according to customer requirements. Adjustment of pH value has no effect on liquid.

4. nano alumina transparent liquid XZ-LY101 high hardness, good size stability, can be widely used in all kinds of plastic, rubber, ceramics, refractories and other products of reinforcing and toughening

5. nano alumina transparent liquid XZ-LY101 to improve the density of the ceramic, smooth and bright, cold and hot fatigue, fracture toughness, creep resistance and high polymer material product wear resistance is particularly significant

6. nano alumina transparent liquid XZ-LY101 is far infrared emitting material with excellent performance, as far infrared emission and insulation materials are used in chemical products and in high pressure sodium lamp. In addition, alumina has high resistivity and good insulating properties, which can be used in the main parts of YGA laser crystal and integrated circuit board.

7. improve the UV curable coating scratch resistant ability and durability, the UV curing coating is widely used in areas such as highly wear-resistant, plastic floor, dosage: according to the user to add and use measurement formula.

Keep in storage:

This product at 5 degrees -35 degrees Celsius in the long-term stability of the indoor storage.

|